Reuse Center’s New ‘Skin’ Is More than Just a Pretty Face

/One of the more visible aspects of the ongoing renovation of the Reuse Center at Boston Building Resources is the installation of new exterior wall and roof panels. These panels are more than just a replacement for the previous tan metal exterior—they are a key component of the building envelope that will vastly increase the energy efficiency of the structure.

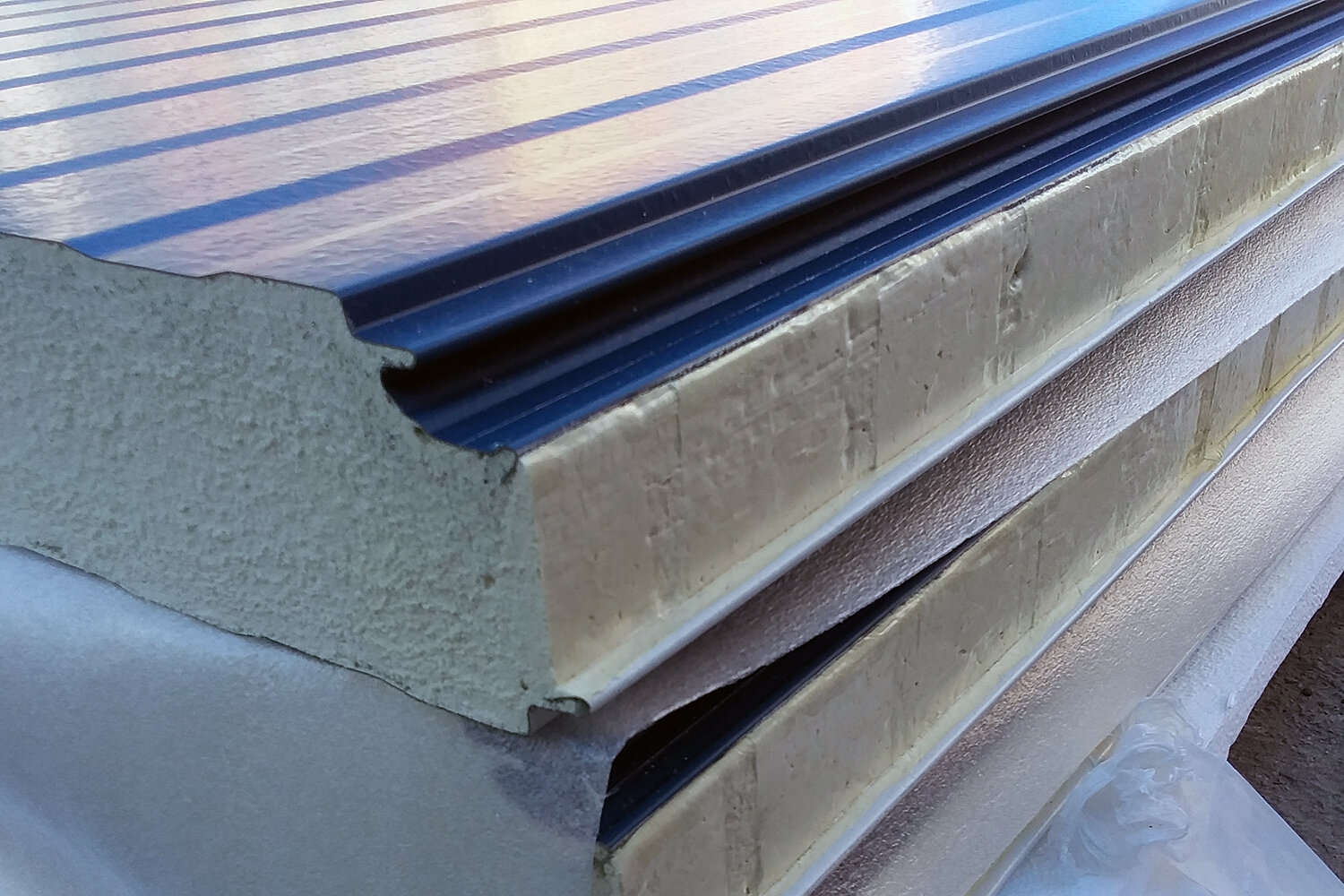

These panels can be thought of as a “foam sandwich.” Two pre-finished steel facings enclose a layer of polyurethane foam that is four inches thick in the wall panels, providing an R-31 insulation value, and five inches thick in the roof panels for a rating of R-38. The manufacturer, Metl-Span, uses a zero-ozone-depleting polyurethane foam.

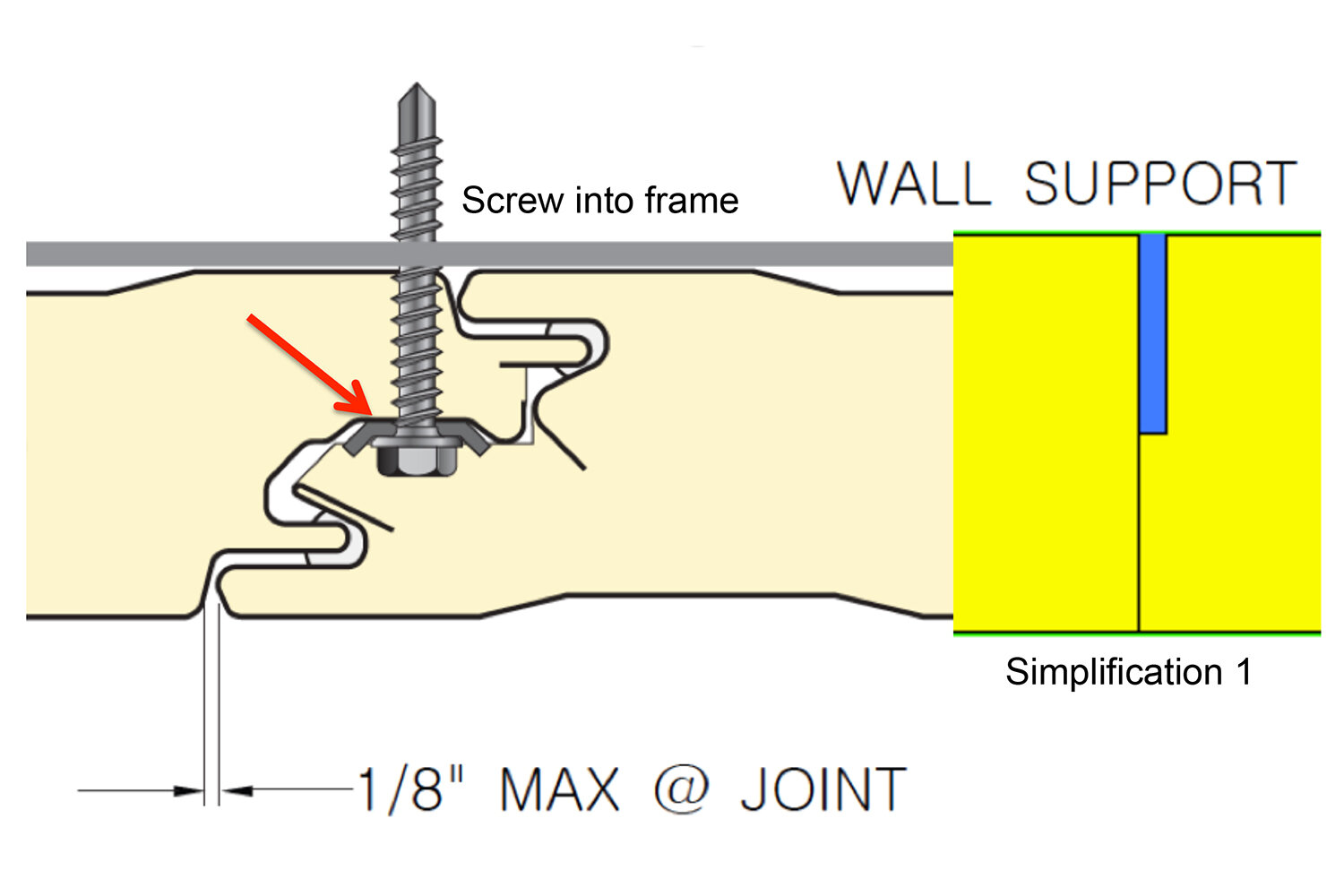

The joints where the wall panels meet are a double tongue-and-groove configuration. This allows for the application of sealant within the grooves, creating an impenetrable barrier that keeps the elements out and keeps heated and conditioned air in. Roof panels have a standing seam with an interlock that creates a physical barrier to precipitation while an inner tongue-and-groove joint completes the seal.

In addition to the panels themselves, the way they are fastened to the building’s frame is designed to minimize energy loss. Screw heads are covered by the overlapping edge of the adjacent panel. This prevents heat from escaping the building envelope through the screws themselves—a process known as thermal bridging. The amount of heat that can pass through a screw may seem miniscule, but, with thousands of screws used throughout the structure, the cumulative effect of thermal bridging could undermine energy performance.

Having a tightly sealed building envelope is an essential aspect of achieving a net zero energy and carbon standard in the renovated Reuse Center. Energy use is minimized through insulation and air sealing so that the building’s annual energy demand can be met entirely through a rooftop solar array.

A grant from the Massachusetts Department of Environmental Protection covered a major portion of the cost of purchasing and installing the insulated panels. We are still seeking contributions to fully fund the renovation project.